- NEW YEAR, STILL OVERWHELMED

- Happy New Year and hello 2022! Typically, the time between late December and early January gives folks in the freight industry a chance to catch their breath, if only for a moment. Unfortunately, the high demand for goods from consumers and companies looking to restock after the holiday shopping has made the respite more like a quick sigh. Volumes are relatively flat compared to this time last year, but capacity continues to be the story, with trucks being scarce as drivers take some needed downtime, weather puts a kink in well-laid plans across the U.S. and the dreaded “C” word hampers labor efforts, not just with drivers, but across all parts of the supply chain.

- RATES STILL RISING

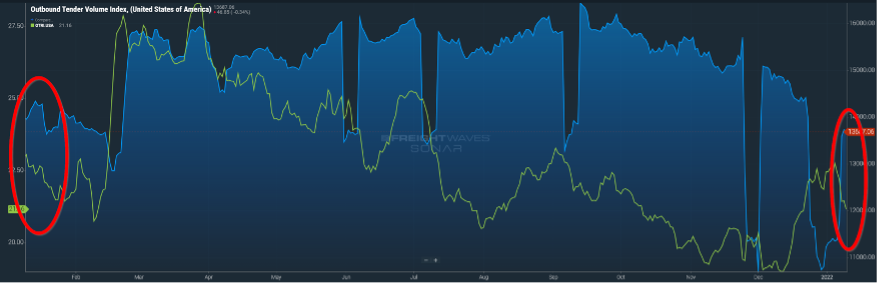

- If one were to look simply at the volume and tender rejection trends (Figure 1.1), it would be easy to assume that rates would begin to decrease. Rejection rates are down about eight percent versus this time in 2021, but that is more a product of contracted rates being rebid by carriers than an increase in capacity. As you can see in Figure 1.2, spot rates have risen sharply since the middle of 2021, sitting currently at $3.81 per mile on the van side.

Figure 1.1

Figure 1.1

Figure 1.2

- STILL FACING PORT PRESSURE

- We have started to see a slight decline in the cost of shipping containers. Figure 2.1 shows the cost of a container from China heading to our west coast is down 25 percent versus the peak rates reached in the early fall months of 2021. Imports will still show increases in the early part of 2022, but not to the levels forecasted several months ago. January and February should show year-over-year (YoY) increases, with March being down slightly versus last year as the Lunar New Year pause impacts ocean shipping. It is a cautionary tale, as we could see more of the “stop and start” with imports play out as Chinese shipping ports deal with labor shortages and potential stoppages due to quarantine measures.

- To further expand on port activity, we are seeing a shift from traditional west coast ports to less populated ports on the east coast. An example of this can be seen by looking at the expected TEU volume index for the next seven days, it is forecast to be 16 percent higher for volume coming from China to the port in Los Angeles. In comparison, for the same seven-day period, the port of Charleston (SC) is anticipating an increase YoY of 121 percent. This is being reflected in the container cost heading from China to the east coast. While it has decreased, it remains almost $3,000 higher to procure a container versus the cost to rent a container heading to the west coast. It’s a trade-off, as containers are getting off-loaded and product getting to their destination quicker than if it is destined for the west coast. The question becomes is the $3,000 additional charge worth the time savings?

January 2022 Freight Market Update

||